Work With One of the Finest Die Cutting Companies In New York

Printing is a fascinating and ever-evolving process which never fails to impress us. If printing is a show-stopper, then print finishing is the one that takes the center stage.

One of the common option adopted by our clients in print finishing is die cutting. You can use it to produce unique shapes, message windows, multidimensional surfaces, boxes and much more. As crude as it may sound, die cutting isn’t an complex process, it is like making a cookie cutter for your printed material.

Our Die Cutting Process

Die cutting is a really crucial part of VSL Print finishing process when creating something for print. It comes after a print-job that has been run through the printing-press and is ready for trimming and finishing in whatever fashion the piece requires.

Our die cutting process entails the use of a specialized thin razor-sharp steel blade tool known as a die. The die is shaped, affixed on a base and mounted to a printing press similar to an antiquated letterpress and is then used to shape the print material using a press.

We provide Custom Die Cutting Services

You can use die cutting as both a decorative and functional process . It is a reasonably flexible technology which can achieve tons of diverse shapes and purposes for your finishing.

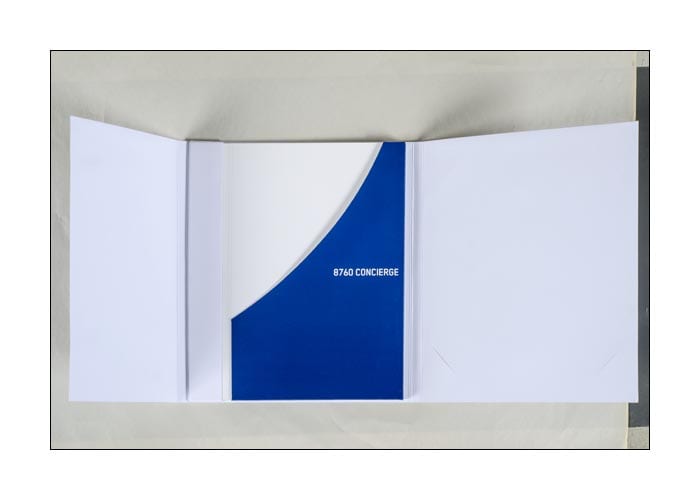

You can create flaps, holes, rounded corners, windows or pop-ups for solely attention-grabbing, or decorative, as well as the core process for creating the shapes of products like boxes, folders, bags, etc.

We Can Help With Custom Die Cut Projects

If you’ve ever seen an advert in the-shape of a baseball, or a kids-menu in the shape-of an animal, then you’ve seen our die cutting ability.

Other typical examples of our die cutting services include slits in a printed piece to hang on a doorknob, the curved corners of business-cards, or the perforations along the-top of a business form.

Yes, these are all cut with dies. In each of these, we curved the metal and bent them into your desired shape and then placed onto a kind of press that cuts the paper to the form. The limitation relate to the manipulation and bending of the metal itself.

Die cutting is mostly preferred by clients for larger, less intricate shapes and is therefore not suitable for very complex shapes.

If you’ve a very intricate design in mind, then you can opt for other cutting options, such as laser cutting. But for most print finishing projects, this is the most-straight forward and cost effective technique.

Contact VSL Print now to talk about your Die Cutting Projects

Besides die cutting services, we also provide other finishing services such as Coating, Embossing, Engraving, Foil Stamping, Gilding, Indexing, Laminating, Letterpress and much more.

Our team has combined decades of experience in Die Cutting projects and we can help advise you in your next project. Reach out to us today and we can give you feedback regarding your plans. Contact us today – we look forward to working with you!

Common FAQs

What is the process of die cutting ?

How does die cutting work?

The

What does die cut sticker mean?

A

Is it die cut or dye cut?

This is a typical grammatical error. The word dye is used in the context of inks and changing the color of a material.

What materials can be die cut?

Plastic and plastic films are among the most common materials used for

What is die cut

“Die cut” really just means to cut a specific piece of material. In this case, adhesive paper will be cut into specific forms and shapes with a metal die. This is completed by either cutting out a shape or removing pieces to form the actual shape of a piece of artwork.

How does rotary

Rotary

What is laser

What is laser